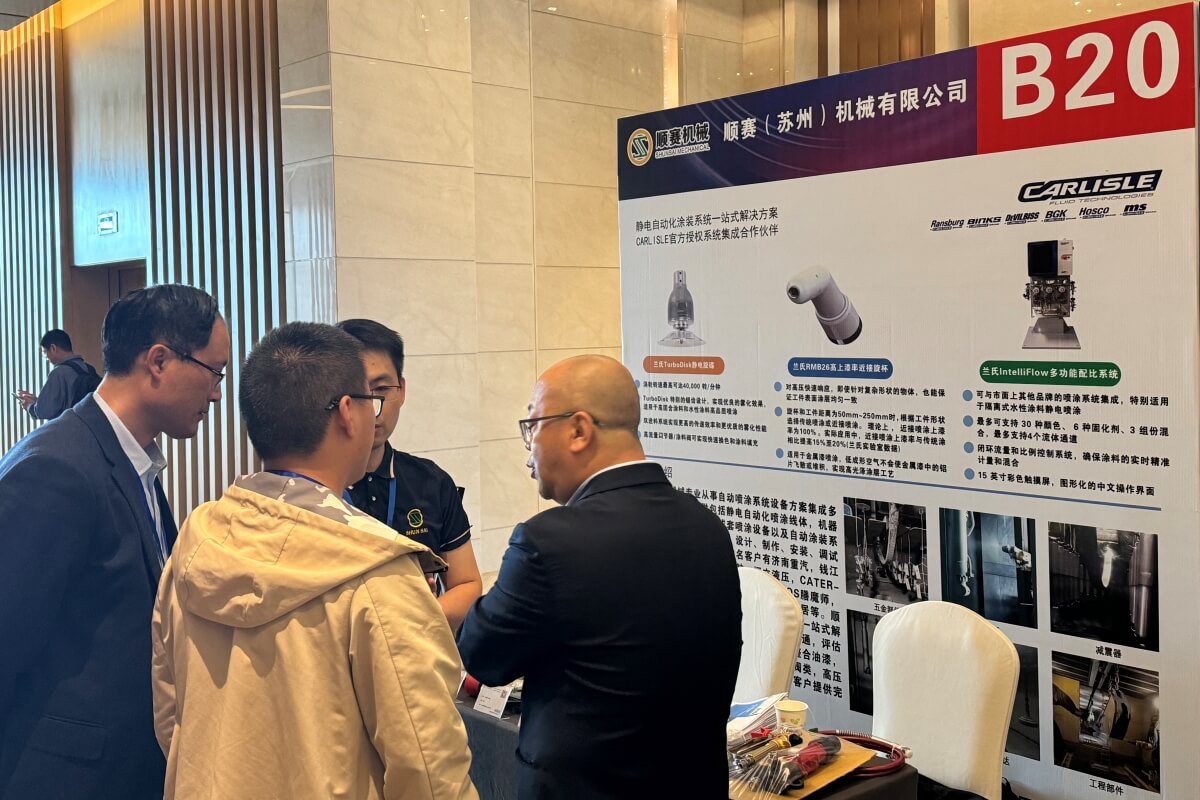

From October 16th to 18th, the 23rd China Coatings and Painting Technology Information Exchange Conference was held in Suzhou, China. Over 500 experts, scholars, and corporate representatives from China’s coatings and painting industry gathered to discuss the latest technological advancements and future trends of the industry. Themed “Low Carbon, Environmental Protection, Safety, and Intelligence,” the conference emphasized the crucial role of new technologies in driving high-quality development within industry. At this grand event, SUNSEK, as Ransburg authorized cooperative integrator, showcased its latest advanced equipment including the RMB26 rotary atomizer, RF2 multifunctional ratio system, and TurboDisk, becoming a highlight of the conference.

The RMB26 rotary atomizer became a major highlight of the conference with its unique design and outstanding performance. The RMB26 rotary atomizer features an innovative CB curve control system, which significantly enhances the precision and efficiency of coating application, especially on complex workpiece surfaces. According to SUNSEK, this new rotary atomizer’s design allows for more uniform paint adhesion on the workpiece surface, greatly reducing paint wastage while also improving the quality of the coating.

The RMB26 rotary atomizer became a major highlight of the conference with its unique design and outstanding performance. The RMB26 rotary atomizer features an innovative CB curve control system, which significantly enhances the precision and efficiency of coating application, especially on complex workpiece surfaces. According to SUNSEK, this new rotary atomizer’s design allows for more uniform paint adhesion on the workpiece surface, greatly reducing paint wastage while also improving the quality of the coating.

The RF2 multi-functional mixing system can be integrated with various brand spraying systems, making it particularly suitable for isolated water-based paint electrostatic spraying. This system can precisely control the mixing ratio of multiple colors and materials, meeting the precise color matching needs of complex coating requirements, thereby greatly enhancing production efficiency and consistency of the coating effect. This highly automated solution not only reduces human errors but also provides manufacturers with greater operational flexibility.

The display of the TurboDisk equipment also attracted the attention of attendees. This device adopts high-speed rotation technology with a special serrated design, significantly improving the quality of the atomization effect. Its optimized design enables rapid color changes and material savings, making it ideally suited for production environments that require frequent paint or color changes.

During the conference, SUNSEK showcased its spray-painting technology solutions tailored for various industries to numerous clients from different sectors. The presentation not only covered a wide range of spray-painting techniques and knowledge but also included how to customize personalized spray painting plans according to customer needs. Through a series of video demonstrations, physical displays, and explanations by the professional team, participants were filled with anticipation for potential future collaborations.

During the conference, SUNSEK showcased its spray-painting technology solutions tailored for various industries to numerous clients from different sectors. The presentation not only covered a wide range of spray-painting techniques and knowledge but also included how to customize personalized spray painting plans according to customer needs. Through a series of video demonstrations, physical displays, and explanations by the professional team, participants were filled with anticipation for potential future collaborations.